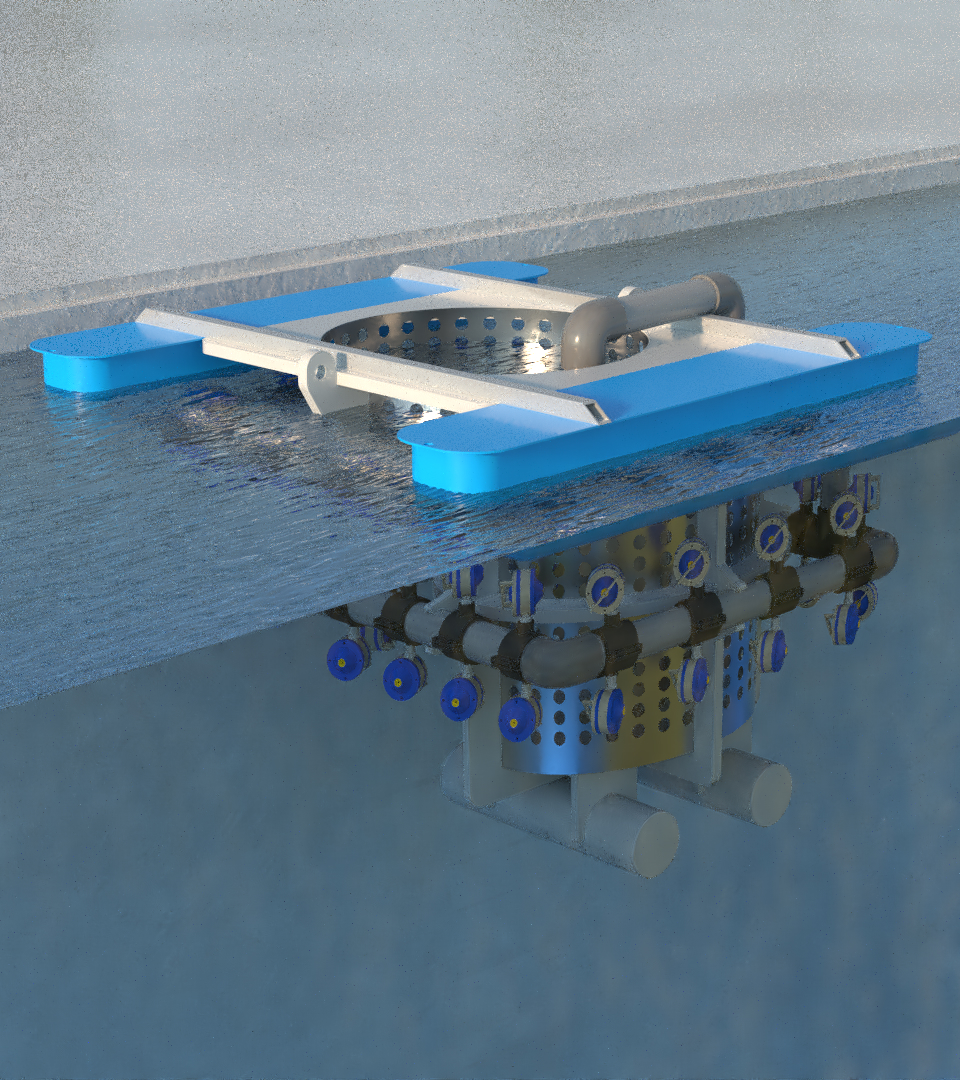

Inventor developer and manufacturer of robust, stable eco-friendly Nanobubble systems

Filtoflex’s Nanobubble technology increases productivity across a wide range of industrial and commercial processes. It includes pre-treatment, treatment and post-treatment solutions. It is safe, chemical-free, and sustainable.

Filtoflex’s experience and innovative solutions make us stand out

Chemical-free, energy-efficient & sustainable solution

Improvement in efficiency, efficacy & productivity

Custom-made, specifically tailored to your needs

Requires minimal maintenance & operating costs

Treats both water & wastewater